surface grinding machine ppt

Types of grinding Machine Grinding machines according to quality of surface finish may be classified as 1. Boring is used to enlarge an existing hole.

Surface Grinding Operations Ppt Download

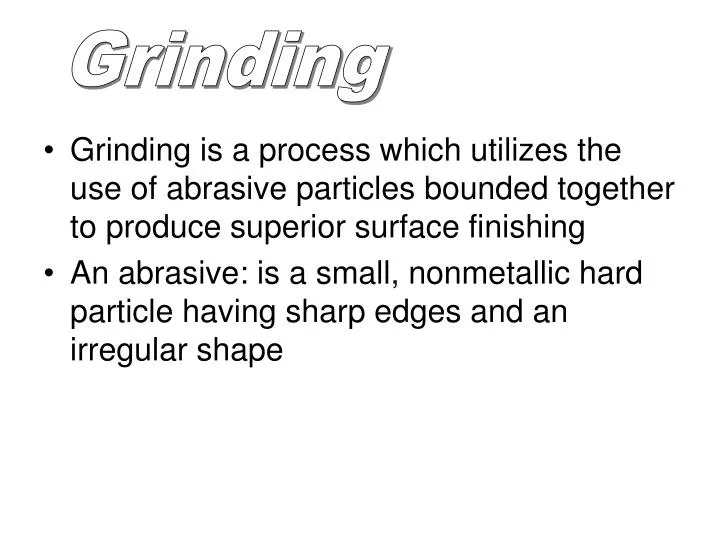

Advent of advanced grinding machines and grinding wheels has elevated the status of grinding to abrasive machining where high accuracy and surface finish as well as high material removal rate can be achieved even on an unhardened material.

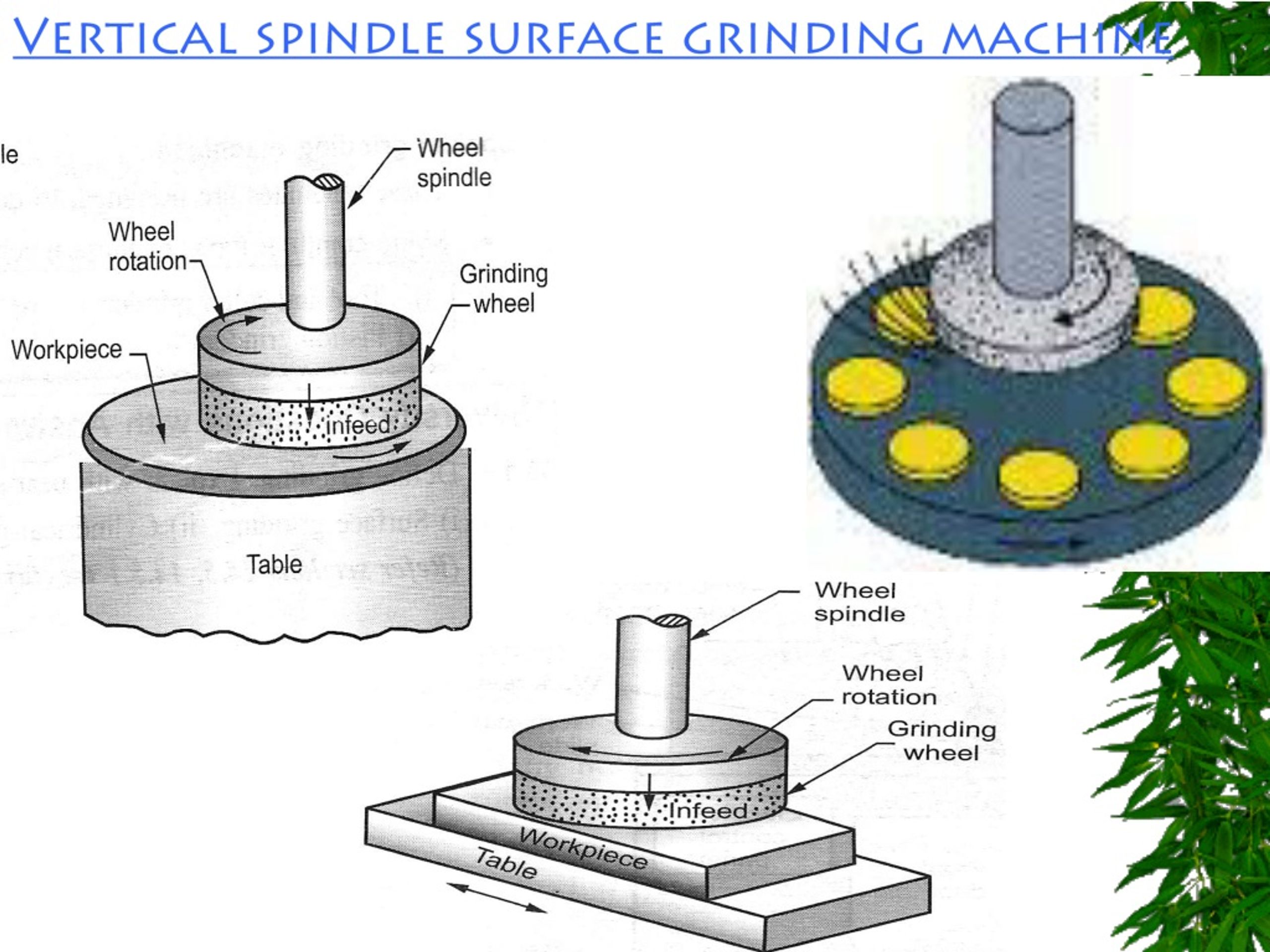

. Tool rests on bench or pedestal grinders shall be set no more than 116 inch from the wheel. Vertical spindle and rotary table type Horizontal spindle surface. Extremely close precision along with a highly-skilled workforce ensures a quality part part-to-part.

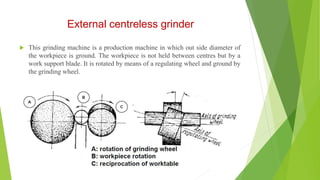

Surface grinding but can also be used for offhand grinding of flat surfaces. Introduction A grinding machine often shortened to grinder is any of various power tools or machine tools used for grinding which is a type of machining using an abrasive wheel as the cutting tool. The work piece is fed against a constantly rotating abrasive wheel so that a thin layer of material is removed from the it.

An abrasive is a material whose particles are extremely hard and can be used to machine materials such as hardened steel glass carbides ceramics etc. Horizontal spindle and rotary table type 3. The grinding machine is used for 1.

There are several types of grinding machines such as surface grinders bench grinders cylindrical grinders tool and cutter grinders jig grinders gear grinders profile grinders and special purpose grinders. Surface grinding machine How to Use surface Grinder Machine operation. Notice the difference between Boring and Drilling.

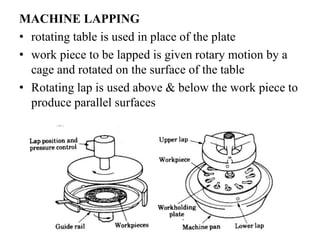

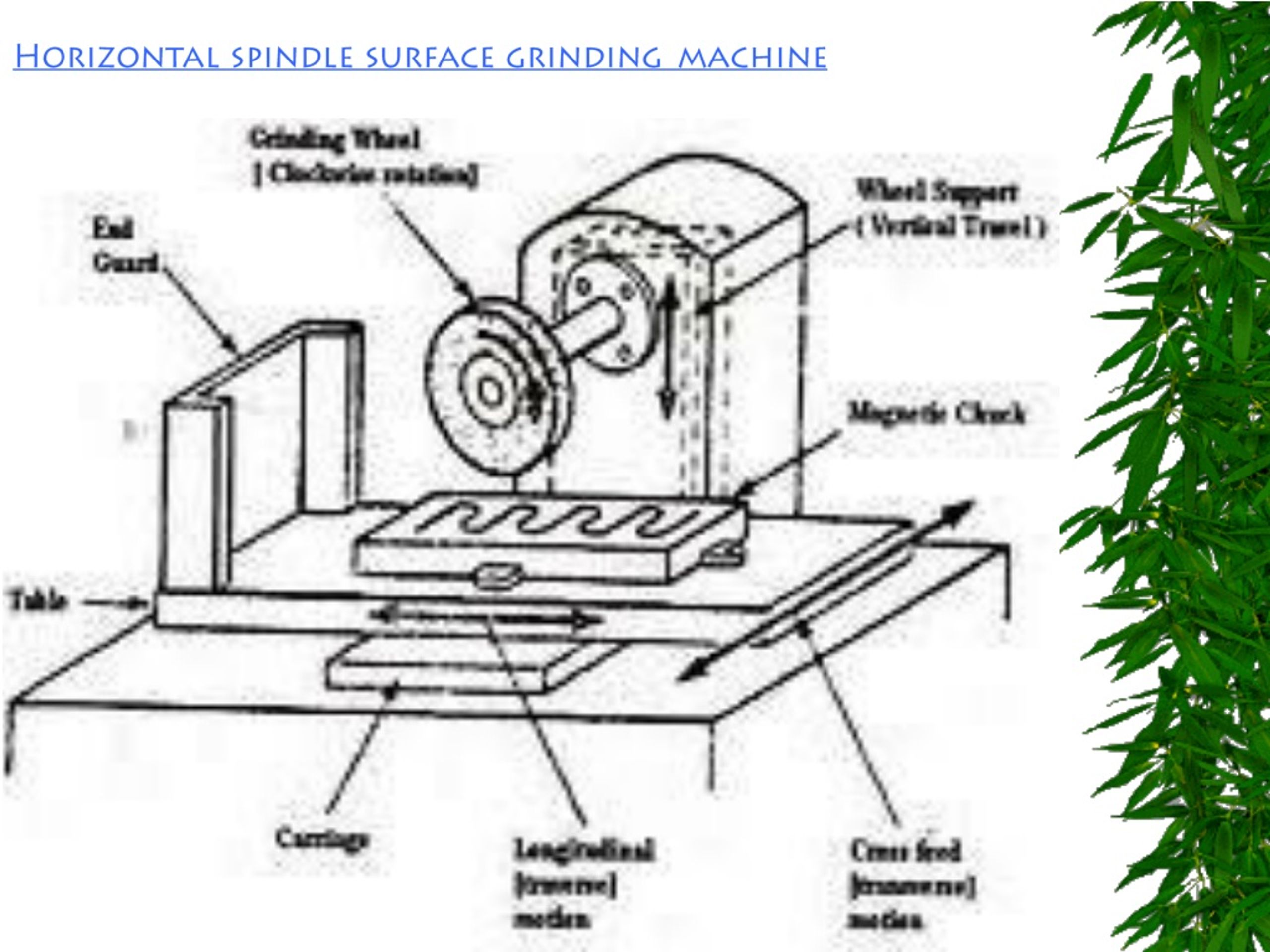

Precision grinder Cylindrical surface internal tool cutter disc thread cam shaft grinder 4. It is basically a finishing process employed to produce high accuracy and surface finish. Vertical spindle Reciprocating table surface grinding machine These machines are designed for quick flat grinding of work pieces.

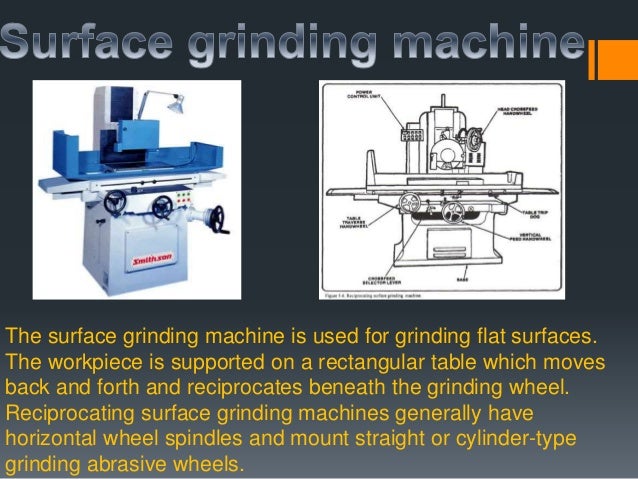

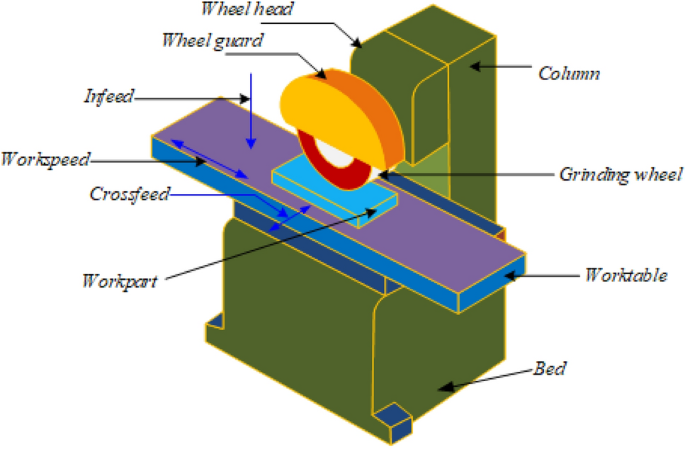

Rough grinder Floor and bench swing frame portable abrasive belt grinder 2. SURFACE GRINDING MACHINE This machine may be similar to a milling machine used mainly to grind. In this process by holding work piece on the table by the surface or perimeter of rotating grinding wheel material can be removed by the abrasive grinding action is used in surface grinding.

WORKING PRINCIPLE OF surface grinding PROCESS 5. Longitudinal travel 550mm to 800mm Spindle drive. PRINCIPLE OF SURFACE GRINDING Principle.

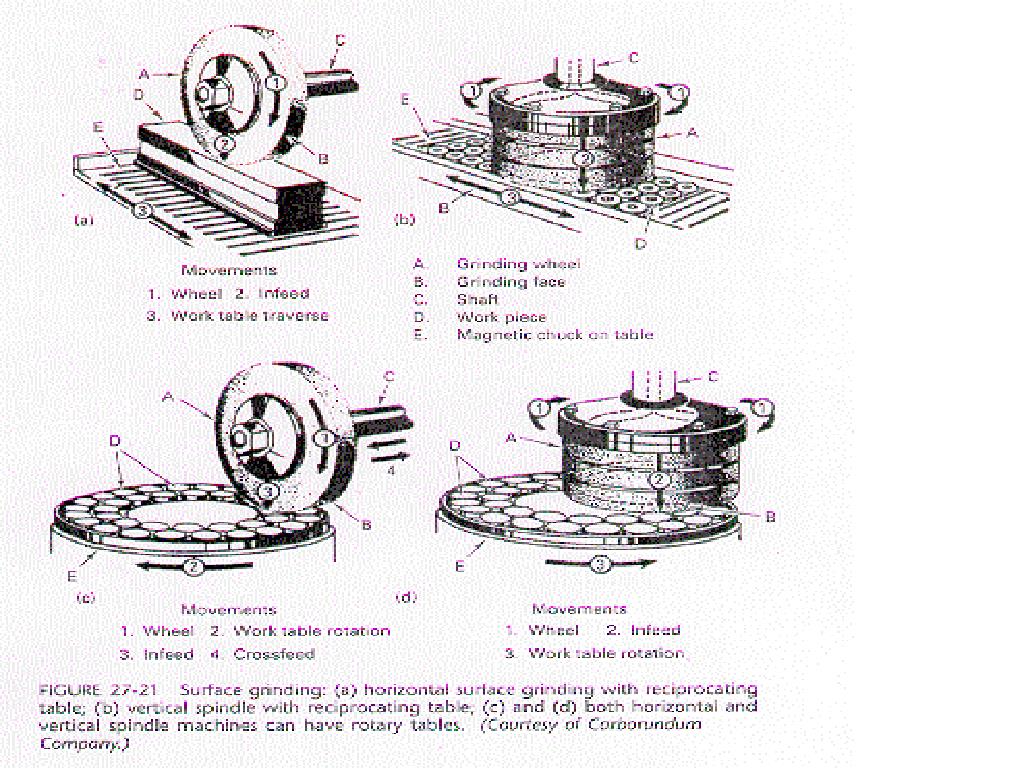

View Grinding Machineppt from MECHANICAL 123 at Nirma University Ahmedabad. Horizontal spindle and reciprocating table type 2. The surface grinding is a special type of grinding process.

Broadly there are two different types of cylindrical grinding machine as follows. Vibratory Tumblers Deburring and Burrs. Vertical spindle and reciprocating table type 4.

Grinding Classification of grinding machine. Grinding Machine Grinding is a metal removal process by the action of a rotating abrasive wheel. Surface grinding machines are employed to finish plain or flat surfaces horizontally vertically or at any angle.

Grinding operation may be used for removing a thick layer about 05 mm of material in general class of work. 1Plain centre type cylindrical grinder 2Centre type universal grinder 9 10. Flat Angular Irregular surfaces 8.

PowerPoint PPT presentation free to view What are the Applications of Grinding Wheels - Abrasive cutting additionally recognized as grinding is the method of scraping steel from small chips with irregularly fashioned abrasive particles. Free Abrasive Grinding Flow Superfinishing Process. Plain or beveled faces are available.

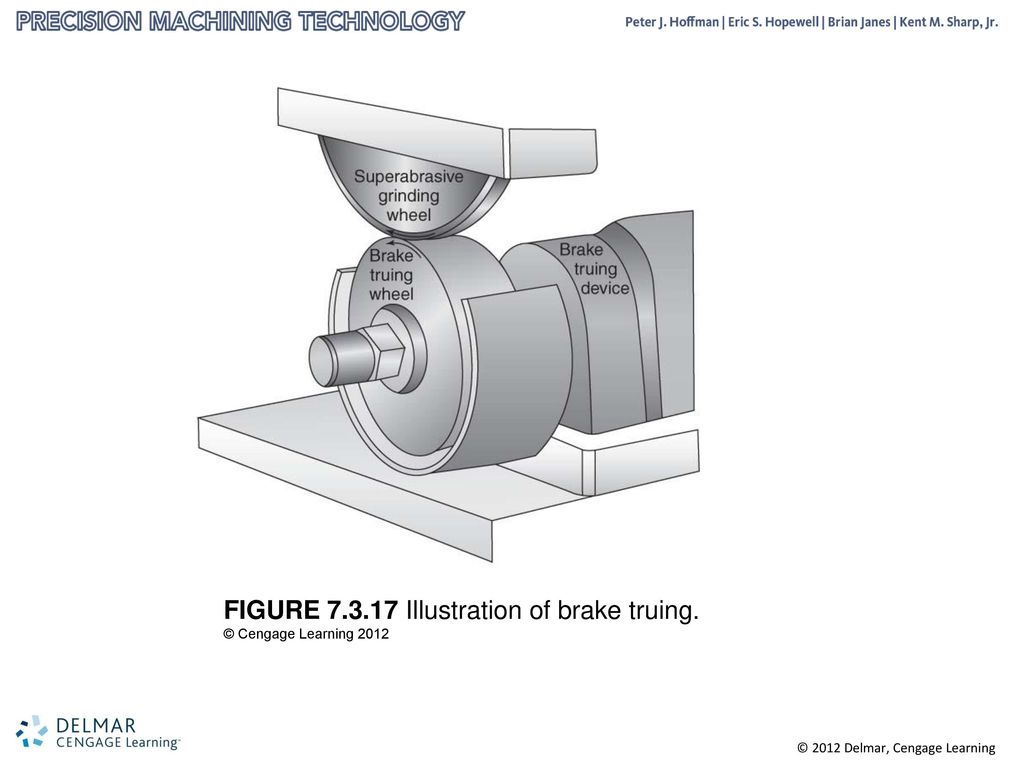

However advent of new generation of grinding wheels and grinding machines. Roughing and finishing flat cylindrical and conical surfaces. Each grain of abrasive on the wheels surface cuts a small chip from the work piece via shear deformation.

Grinding machine is employed to obtain high accuracy along with very high class of surface finish on the work piece. Rough Non-precision grinding 2. SURFACE GRINDING MACHINE FIG.

For parts requiring a surface ground finish or require a tighter tolerance than 001 TCI processes material on its surface grinder. A grinding disc is a sharp cutting tool with thousands of cutting edges on the side of the surface. Grinding Machines Grinding Grinding is a surface finishing operation where.

15 KW to375 KW Wheel clearance. Surface grinding machine generally consists of a base table. Special training is required before using the surface grinder.

With a resinoid bond it is useful for snagging. Abrasive wheel machinery shall not be operated without the appropriate guards in place. Drilling is performed with a rotating cylindrical too called a drill or drill bit that has two cutting edges on its working.

The grinding wheel consists of sharp crystals called abrasives held together by suitable bonding. Ask shop staff to demonstrate proper use of this tool. Finishing internal cylinders or bores.

Precision grinding RoughNon-precision grinding To remove more stock than other grinding aFloor stand and bench grinders bPortable and flexible shaft grinders cSwing frame grinders dAbrasive belt grinders. Dish The chief use of the dish wheel type number 12 is in tool work. These grinding machine ppt are eco-friendly and are energy-saving machines for commercial uses.

ONSITE CRANKSHAFT GRINDING MACHINE 1 - in situ crankshaft grinding portable crankshaft grinder onsite crankshaft grinding machine crankshaft grinder machine Email us. Manufacturing Technology Grinding Machines Grinding Machines are also regarded as machine tools. Grinding Safety Guidelines 1.

Tool and Cutter Grinders. The bulk grinding wheel workpiece interaction as given in Figure 2 can be divided into the following. TCIs surface grinding capability allows us to hold very close precision tolerances.

Cnc Grinding Machine PowerPoint PPT Presentations. Up to 200mm Cross traverse is manual for infeed and powered for positioning Hydraulic drive for table. Flaring Cup The flaring cup wheel type number 11 is commonly used for tool grinding.

Its face may be plain or beveled. TYPES OF CYLINDRICAL GRINDING MACHINE This machine is used to produce external cylindrical surface. The crankshaft after removal from the engine block was properly packed and transported to the designated workshop having surface crankshaft grinding machine.

The grinding machine ppt are provided with powerful motors and working mechanisms that efficiently grind stones spices leaves and so on into fine powders for a variety of uses. A distinguishing feature of grinding machines is the rotating abrasive tool. CNC Gantry Machine CNC machine.

According to the quality surface finish. Type iii Surface Grinder. The surfaces may be straight tapered steps or profiled.

There are four different types of surface grinders. Fayed Page 3 Drilling - An Introduction Drilling is a machine operation used to create a round hole in a work-part.

The Metric System Si Units And Unit Conversions Powerpoint Teaching Homeschool Metric System Middle School Activities

Fluid Flywheel Of An Automobile Construction And Working Of Fluid Coupling Of An Automobile Automatic Transmission Fluid Torque Converter Flywheel

Ppt Machine Tool Powerpoint Presentation Free Download Id 961349

Design And Fabrication Of Low Cost Surface Grinding Machine Ppt Download

A Novel Chaotic Henry Gas Solubility Optimization Algorithm For Solving Real World Engineering Problems Springerlink

Surface Grinding Operations Ppt Download

Surface Grinding Machine Working Classification 3d Animation Youtube

Surface Grinding Operations Ppt Download

Ppt Grinding Powerpoint Presentation Free Download Id 2175456

Grinding Ppt Video Online Download

Ppt Grinding Powerpoint Presentation Free Download Id 2175456

Ppt Machine Tool Powerpoint Presentation Free Download Id 961349